Silencers for pneumatics from Festo reduce noise levels and make it easier to maintain your industrial automation system. Festo pneumatic silencers thus reduce the risk of downtime by automatically warning if or when their pressure levels increases too much.

Silencers in pneumatics: excellent components for maximum precision in the application

Pneumatic silencers not only reduce the noise level of the exhaust air, Festo silencers also protect the actuator system from dust particles or dirt that can enter through the valve.

But how does a pneumatic silencer work?

A Festo silencer, for example, is a body/sintered body that uses several chambers separated by baffles to slow down and cool down the escaping gases. This reduces the noise made by the escaping gases and reduces the likelihood of sparks. As silencers are manufactured using porous aluminium, the flow rate of silencers in pneumatics can be widely regulated; as a result, Festo silencers have lower resistance and a minimal impact on the operation of your pneumatic system.

Festo silencers: our highlights for pneumatics

Reduce the noise level of your system with pneumatic silencers from Festo. Our silencers for pneumatics are available in many variants: in narrow and long or short designs, in polymer or die-cast versions. Special open Festo silencers with an outlet opening enable the trouble-free operation of a vacuum generator.

Festo silencer AMTE

High temperature-resistant Festo silencer in metal version for noise level reduction.

Long or short design

Metal design

Operating medium: compressed air

Festo silencer U

Festo silencers for reducing the noise level of your pneumatic system.

Compact design, polymer or die-cast

Barbed fitting or threaded connection

Operating medium: compressed air

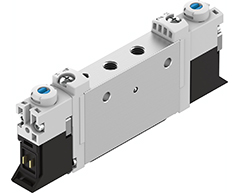

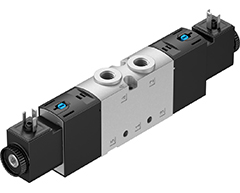

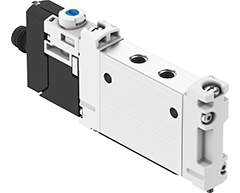

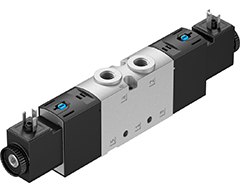

Festo VUVS-LT20-B52-ZD-G18-F7 solenoid valve 577497

Festo VUVS-LT20-B52-ZD-G18-F7 solenoid valve 577497  Kingdom Hex Nipple 11/4" BSP 316 SS, HNSS-114

Kingdom Hex Nipple 11/4" BSP 316 SS, HNSS-114  H-1/4-B non-return valve 11689

H-1/4-B non-return valve 11689  Festo On/off valve MS6-EM1-1/4, 541271

Festo On/off valve MS6-EM1-1/4, 541271  DGSL-8-30-P1A mini slide 543934

DGSL-8-30-P1A mini slide 543934  Festo filter regulator MS4-LFR-1/4-D6-ERV-AS-Z, 529151

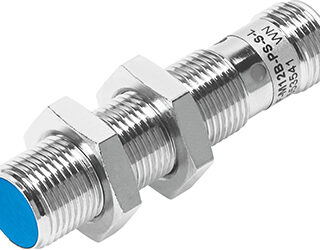

Festo filter regulator MS4-LFR-1/4-D6-ERV-AS-Z, 529151  SIEF-M30B-NS-K-L proximity sensor 553552

SIEF-M30B-NS-K-L proximity sensor 553552  Burkert Type 6213 Solenoid 1" BSP Brass NBR 110VAC, 221636

Burkert Type 6213 Solenoid 1" BSP Brass NBR 110VAC, 221636  Burkert Type 6213 Solenoid 3/8" BSP Brass NBR 24VDC, 221598

Burkert Type 6213 Solenoid 3/8" BSP Brass NBR 24VDC, 221598  Festo Silencer U-1/4-B, 6842

Festo Silencer U-1/4-B, 6842  Festo VACC-S18-120-K4-1UF-NM4ME solenoid coil 8118177

Festo VACC-S18-120-K4-1UF-NM4ME solenoid coil 8118177  Festo One-way flow regulator VFOE-LE-T-R18-Q6, 8068735

Festo One-way flow regulator VFOE-LE-T-R18-Q6, 8068735  Pressure regulator 2416371 LRP-1/8-6

Pressure regulator 2416371 LRP-1/8-6  Festo VUVS-LT25-M32U-MD-G14-F8-1C1 solenoid valve 8035176

Festo VUVS-LT25-M32U-MD-G14-F8-1C1 solenoid valve 8035176  VACF-B-K1-1A-1-EX4-M solenoid coil 8059808

VACF-B-K1-1A-1-EX4-M solenoid coil 8059808  Festo NPQM-D-Q12-S14-P10 push-in connector, 570459

Festo NPQM-D-Q12-S14-P10 push-in connector, 570459  Burkert Type 2051 Actuator Double Acting Size 150, 214526

Burkert Type 2051 Actuator Double Acting Size 150, 214526  Festo VUVG-LK10-M52-AT-M5-1R8L-S solenoid valve 8042543

Festo VUVG-LK10-M52-AT-M5-1R8L-S solenoid valve 8042543  VZBM-11/2-RP-40-D-2-M-B2B3 ball valve 4405691

VZBM-11/2-RP-40-D-2-M-B2B3 ball valve 4405691  Pressure regulator VRPA-LM-M5-Q4 8086007

Pressure regulator VRPA-LM-M5-Q4 8086007  Festo SFAM-62-1000L-TG12-2SV-M12 flow sensor 565376

Festo SFAM-62-1000L-TG12-2SV-M12 flow sensor 565376  Festo NPQR-DK-G18-Q4 push-in fitting 8085661

Festo NPQR-DK-G18-Q4 push-in fitting 8085661  Festo VUVS-L25-M52-AD-G14-F8 solenoid valve 575501

Festo VUVS-L25-M52-AD-G14-F8 solenoid valve 575501  Festo VUVS-L30-P53U-MZD-G38-F8-1B2 solenoid valve 575628

Festo VUVS-L30-P53U-MZD-G38-F8-1B2 solenoid valve 575628  ADCA 1/2" BSP Thermostatic Steam Trap Type TH13A, A.42.2100.015

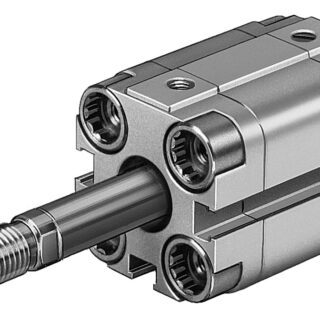

ADCA 1/2" BSP Thermostatic Steam Trap Type TH13A, A.42.2100.015  Festo AEVUZ-16-15-A-P-A compact cylinder 157259

Festo AEVUZ-16-15-A-P-A compact cylinder 157259