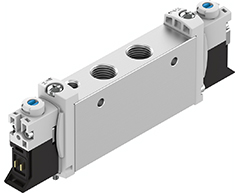

Festo HGL-1/8-1/8-B Piloted check valve 543253

£44.95 Exc. VAT £53.94 Inc. VAT

HGL-1/8-1/8-B Piloted check valve 543253. Check valves are used very frequently in pneumatics. Applications range from the simple shutting off of flow directions and speed control through to logic operations.

Product Description

Piloted check valve HGL-1/8-1/8-B 543253 With sealing ring OL. Valve function=piloted non-return function, Pneumatic connection, port 1=G1/8, Pneumatic connection, port 2=G1/8, Pilot air port 21=G1/8, Type of actuation=pneumatic

Shut-off valve with manual override option.

Valve function: piloted non-return function

Screw-in with male thread

Pneumatically piloted

Pilot air connection: M5, G1/8, G1/4, G3/8, QS-4

Manually actuated exhaust possible with separate accessory

One-way flow control valves

One-way flow control valves combine the functions of flow control valves and shut-off valves in a single component. The compressed air flows freely in one direction. The flow rate can be changed in the reverse direction by an adjusting element. These products are often used in combination with pneumatic cylinders in order to control the speed.

What is a non-return valve or a check valve?

Non-return valve, also known as check valves, is a mechanical device that allows fluid or gas to flow in only one way valve. Stopping reverse flow and protecting against damage or malfunction in piping systems, pumps, and other mechanical equipment.

Types of non-return valves.

Basically, the following valves come under this category:

Check valves, One-way valves, Quick exhaust valves, Shuttle valves (OR valves) and Dual pressure valves (AND valves).

Piloted non-return valves

These valves are used primarily for reasons of safety. The illustration below shows a cylinder which is to lift and lower a weight. In order to prevent the lifted weight from moving down again in the event of pressure failure (e.g. as a result of tubing disconnection or inadvertent exhausting of the system), a non-return valve is fitted at each cylinder connection.

The valve must be connected directly at the air connection of the cylinder in order to prevent other risks.

Caution!

Piloted non-return valves are not permissible for use as safety elements on presses. There are two reasons for this:

First the switching time from the pressure dropping until the actual closing of the valve is 10 to 20 ms, depending on size. During this time, the mass can therefore still drop and traverse a distance which leads to corresponding damage.

Secondly, these valves are not 100% leak-proof. This means that the downward movement may still continue after the valve has closed. These are not negligible amounts by any means. Therefore, a cylinder with a diameter of 63 mm, provided with a 3/8″ non-return valve should be considered as safe for a maximum of 30 minutes. A time period which is, for instance, too short to rescue trapped personnel.

In such a case, a fast-switching 2/2-way valve (stop valve) would be a better solution. However, apart from the pneumatic aspects, there are also a number of electrical factors to be considered. Special rules therefore apply for press controls.

A swing check valve is a type of check valve that is designed to allow fluid to flow through it in only one direction. It consists of a movable disc or clapper, which is attached to a hinge, and a seat around the perimeter of the valve.

More Info

| Weight | 0.03 kg |

|---|---|

| Festo Series |