CRLBN-32 clevis foot 195866

£18.64 Exc. VAT £22.37 Inc. VAT

Festo clevis foot CRLBN-32, 195866 Size 12/16, Mounting position optional. Corrosion resistance class CRC 4 – Very high corrosion stress. Ambient temperature -40 °C … 150 °C. RoHS-compliant

Product Description

Festo clevis foot CRLBN-32 Corrosion resistant, for cylinders CRHD and CRDSNU. Size=32, Assembly position=Any, Corrosion resistance classification CRC=4 – Very high corrosion stress, Ambient temperature=-40 – 150 °C

Cylinder mounting parts and accessories

The attachments and accessories for pneumatic cylinders offered by Festo include mounting elements for drives and sensors, piston rod attachments, linear guides, accessories for direct valve mounting, clamping elements, freewheel units, accessories for cushioning elements and drive-specific accessories.

How does pneumatic cylinder works?

In a pneumatic cylinder, the compressed air is used to exert force on a cylinder piston in order move it in a specific direction. The movement of the piston is transferred to the parts to be moved by a piston rod or a frictional connection. A pneumatic cylinder is a drive operated with compressed air usually up to a maximum of 12 bar in order to generate linear or rotary motion. A distinction should be made between single-acting and double-acting cylinders (work is performed only in one direction or in both directions)

What is a single-acting pneumatic cylinder?

Pneumatic cylinders, also called air cylinders, pneumatic actuators, or pneumatic drives, are relatively simple mechanical devices that use the energy of compressed air and turn it into linear motion. Lightweight and low maintenance, pneumatic cylinders generally operate at lower speeds and less force than their hydraulic or electric counterparts, but are a clean and cost-effective option for reliable linear motion in many industrial environments. The most common design consists of a cylinder or tube that is sealed on both ends, with a cap at one end and head at the other end. The cylinder contains a piston, which is attached to a rod. The rod moves in and out of one end of the tube, actuated by compressed air. Two main styles exist: single-acting and double-acting.

What is a double-acting pneumatic cylinder?

A double-acting cylinder is a cylinder in which the working fluid acts alternately on both sides of the piston. In order to connect the piston in a double-acting cylinder to an external mechanism, such as a crank shaft, a hole must be provided in one end of the cylinder for the piston rod, and this is fitted with a gland or “stuffing box” to prevent escape of the working fluid. Double-acting cylinders are common in steam engines but unusual in other engine types. Many hydraulic and pneumatic cylinders use them where it is needed to produce a force in both directions. A double-acting hydraulic cylinder has a port at each end, supplied with hydraulic fluid for both the retraction and extension of the piston. A double-acting cylinder is used where an external force is not available to retract the piston or it can be used where high force is required in both directions of travel.

More Info

| Weight | 0.106 kg |

|---|---|

| Festo Series |

Festo ISO cylinder DSBC-100-160-PPVA-N3, 1384810

Festo ISO cylinder DSBC-100-160-PPVA-N3, 1384810  Festo VUVG-S18-T32H-MZT-G14-1T1L solenoid valve 8004878

Festo VUVG-S18-T32H-MZT-G14-1T1L solenoid valve 8004878  DRVS-25-90-P semi-rotary drive 1845716

DRVS-25-90-P semi-rotary drive 1845716  DGSL-12-150-Y3A mini slide 543982

DGSL-12-150-Y3A mini slide 543982  Festo filter regulator MS6-LFR-3/8-D7-CRM-AS, 529224

Festo filter regulator MS6-LFR-3/8-D7-CRM-AS, 529224  Festo NPQM-Y-Q10-E-P10 push-in Y-connector 558801

Festo NPQM-Y-Q10-E-P10 push-in Y-connector 558801  EMMT-AS-100-M-HS-RMB Servo motor 5255533

EMMT-AS-100-M-HS-RMB Servo motor 5255533  Syveco Stainless steel CF8M spring check valve 329 BSP 1/2'' 329004

Syveco Stainless steel CF8M spring check valve 329 BSP 1/2'' 329004  Festo VUVS-LK25-M52-AD-G14-1B2-S solenoid valve 8043218

Festo VUVS-LK25-M52-AD-G14-1B2-S solenoid valve 8043218  Festo VUVS-LT20-M52-MD-G18-F7-1C1 solenoid valve 577515

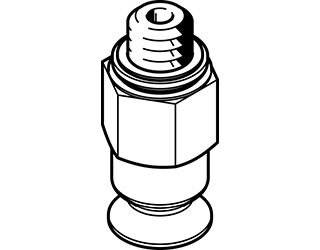

Festo VUVS-LT20-M52-MD-G18-F7-1C1 solenoid valve 577515  Festo VAS-8-M5-PUR-B suction cup 1396086

Festo VAS-8-M5-PUR-B suction cup 1396086