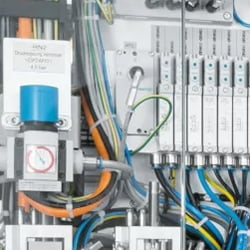

Automation in the electronics industry – From Festo, A German Manufacturer – Special machine building and assembly technology – Automation Innovation cycles of less than one year are now the norm throughout the industry, often leaving you less than six months to set up a new production line. This means you have to move quickly.

Nowadays, you can protect your margins in small parts assembly and electronics production primarily through modularisation and standardisation using flexible, economical automation solutions. That is exactly what we can do for you. Festo Cylinders.

Benefits of standardisation and modularisation

The maths are simple: money saved during development, engineering and software programming will be reflected positively on your balance sheet. Furthermore, your purchasing department benefits from economies of scale. And you can offer your solutions more quickly and flexibly.

Your savings potential in black and white

Automation in the electronics industry – Your success depends largely on the time and effort spent on design engineering and on the products you use. When you focus on standardised products and solutions, you can immediately boost your profit by 20% to 30%. This has also been demonstrated by a study of the industry in Germany by the VDMA.

Electronics industry

Parallel kinematic systems, compact gantries, ready-to-install handling systems: we have rapid and precise solutions on hand for the electronics industry.

Download the study “The future of German machine building” (PDF)

Festo ADN-16-5-I-P-A compact cylinder 536226

Festo ADN-16-5-I-P-A compact cylinder 536226  Festo DFPD-1200-RP-90-RD-F14-R3-EP semi-rotary drive 8065271

Festo DFPD-1200-RP-90-RD-F14-R3-EP semi-rotary drive 8065271  Festo ISO cylinder DSBC-100-200-PPSA-N3, 1384897

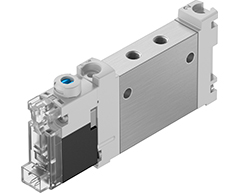

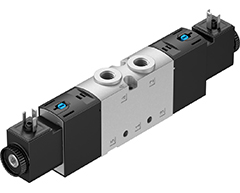

Festo ISO cylinder DSBC-100-200-PPSA-N3, 1384897  Festo VUVS-LT30-M32C-MD-G38-F8-1B2 solenoid valve 8036676

Festo VUVS-LT30-M32C-MD-G38-F8-1B2 solenoid valve 8036676  Festo SMT-10G-PS-24V-E-2,5Q-OE proximity sensor 547862

Festo SMT-10G-PS-24V-E-2,5Q-OE proximity sensor 547862  DRVS-16-270-P semi-rotary drive 1845715

DRVS-16-270-P semi-rotary drive 1845715  Festo filter regulator MS4-LFR-1/4-D7-CRV-AS-Z, 529155

Festo filter regulator MS4-LFR-1/4-D7-CRV-AS-Z, 529155  Kingdom Square Head Plug 11/4" BSP 316 SS, SHPSS-114

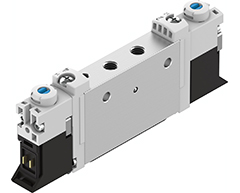

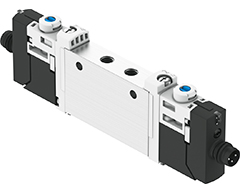

Kingdom Square Head Plug 11/4" BSP 316 SS, SHPSS-114  Festo VUVS-LT20-B52-ZD-G18-F7-1C1 solenoid valve 577518

Festo VUVS-LT20-B52-ZD-G18-F7-1C1 solenoid valve 577518  Festo VACC-S18-120-A1-2A solenoid coil 8040582

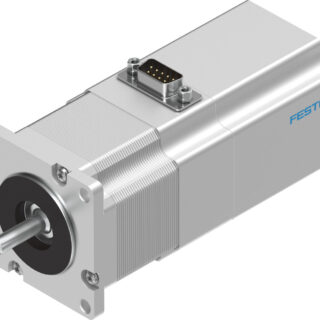

Festo VACC-S18-120-A1-2A solenoid coil 8040582  EMMT-AS-60-L-LS-RSB servo motor 5242214

EMMT-AS-60-L-LS-RSB servo motor 5242214  Festo DSR-25-180-P semi-rotary drive 11911

Festo DSR-25-180-P semi-rotary drive 11911  EMMS-ST-57-S-SB-G2 stepper motor 1370476

EMMS-ST-57-S-SB-G2 stepper motor 1370476  Festo VUVG-L10-T32C-AT-M5-1R8L solenoid valve 577347

Festo VUVG-L10-T32C-AT-M5-1R8L solenoid valve 577347  Inoxpa 11/2" RJT Actuated Valve, VA481-110652040-SR

Inoxpa 11/2" RJT Actuated Valve, VA481-110652040-SR  Festo SMT-10M-NS-24V-E-2,5-L-OE proximity sensor 551377

Festo SMT-10M-NS-24V-E-2,5-L-OE proximity sensor 551377  Festo VN-T2-BP-NRH mounting plate, 196951

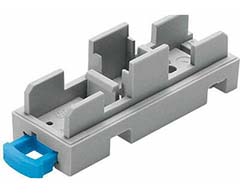

Festo VN-T2-BP-NRH mounting plate, 196951